Cryogenic Valve

Technical parameters and characteristics

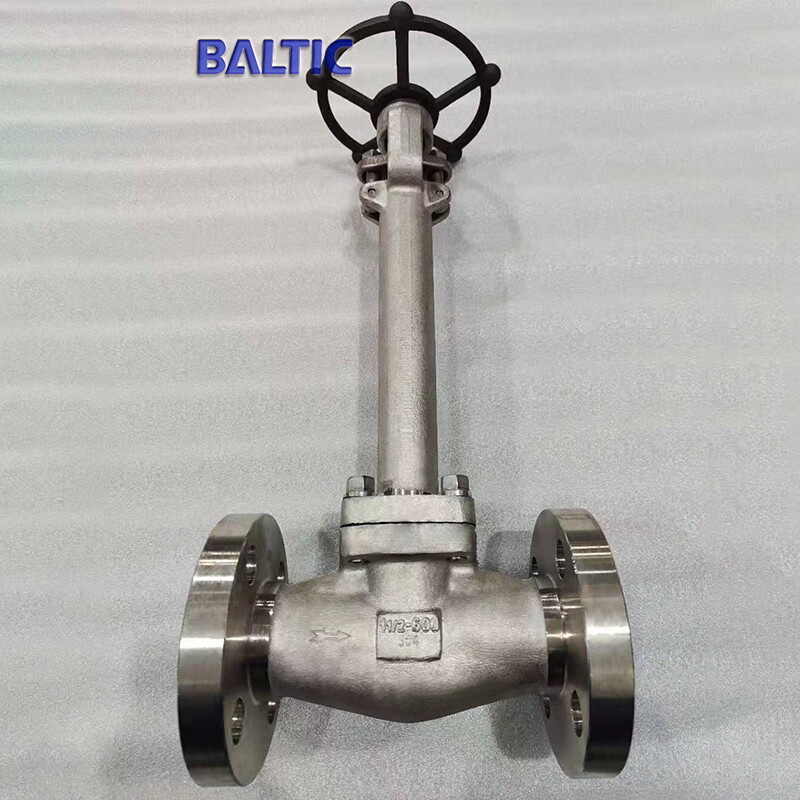

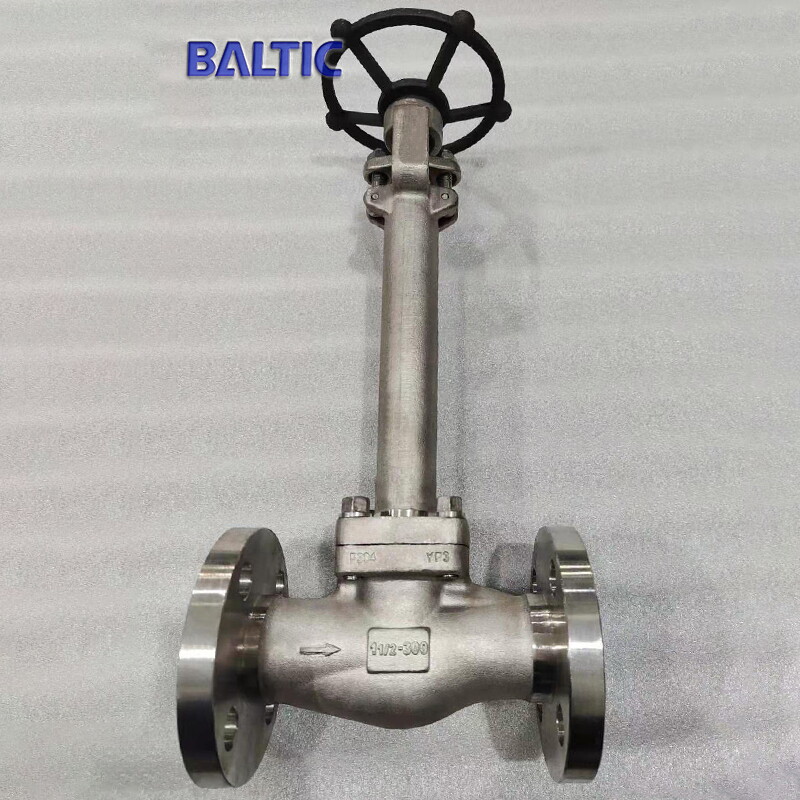

| Product | Cryogenic Globe Valves | |

| Nominal diameter | NPS 2 to 24 Inches | DN50 to DN600 |

| Design temp. | -196℃ | |

| Design pressure | Class 150 to 1500 | PN 16 to PN250 |

| Materials | A351 CF8, CF8M, CF3M, CF8C, CN3MN, CK3MCUN, CN7M, A890 4A(CD3MN), 5A(CE3MN), 6A(CD3MWCuN) |

|

| Design standards | BS 1873, ASME B16.34 | DIN 3356 |

| Face to Face | ASME B16.10 | EN558 series |

| Connection ends | ASME B16.5, ASME B16.25 | EN1092 series |

| Test standards | API 598, ISO 5208 | EN12266-1 |

| Operation | Hand wheel, bevel gear, electric, pneumatic | |

| Applications | LPG, LNG | |

| Special treatment | Deep cryogenic treatment | |

| Special test | Impact test | |

| Function 1 | OS&Y, bolted bonnet, rising stem | |

| Function 2 | Short stroke for quick opening or closing | |

| Function 3 | For big size and high pressure: relief cone = internal bypass | |

| Function 4 | Disc sealing could be: flat sealing, throttle cone=regulating disc | |

| Function 5 | The body seat could be a threaded seat or welded seat. | |

| Structure feature 1 | Extended Bonnet | |

| Structure feature 2 | Provided with drip plate | |

| Structure feature 3 | Fire Safety & Anti-static Design | |

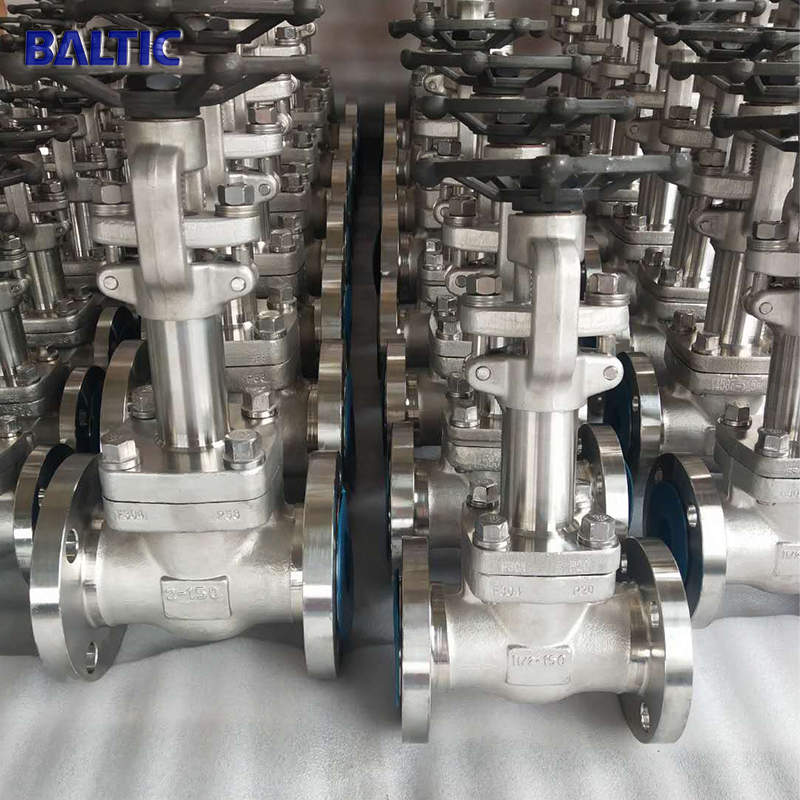

Technical parameters and characteristics

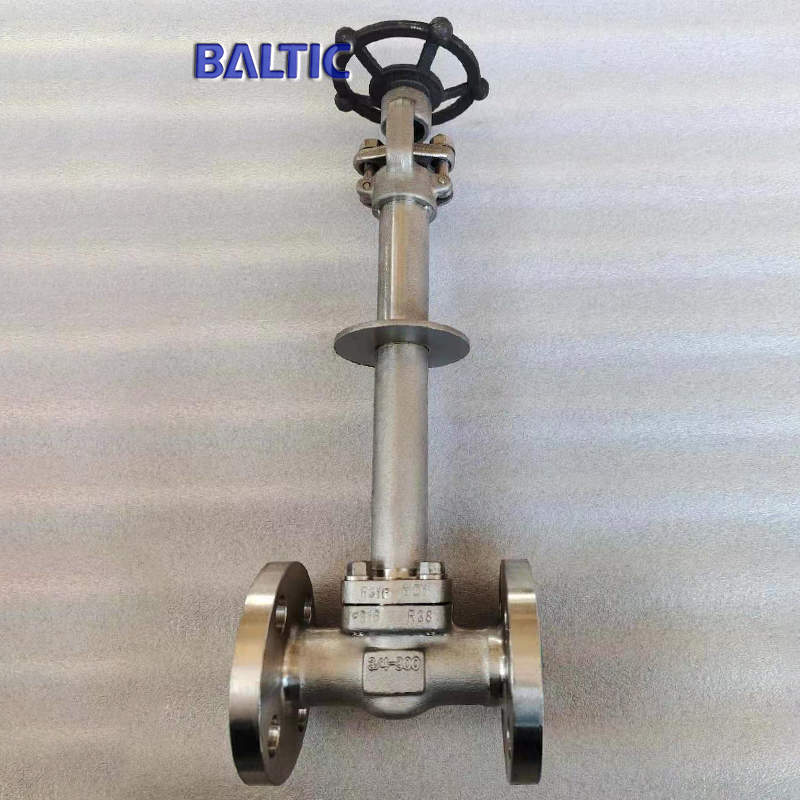

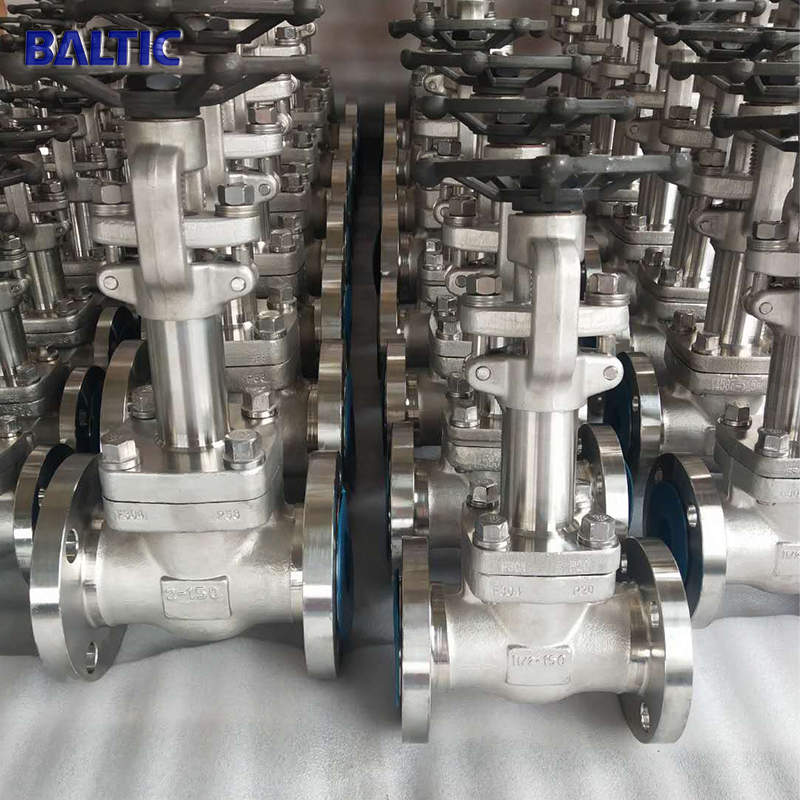

| Product | Cryogenic gate valve |

| Nominal diameter | 2 Inch to 48 Inch |

| Design temp. | -196℃ |

| Design pressure | Class 150 to 1500 LB |

| Material | Stainless steel |

| Design standard | API 600 |

| Face to face | ASME B16.25, ASME B16.10 |

| Connection end | BW, Flange |

| Test standard | API 598 |

| Operation | Hand wheel, gearbox, electric |

| Applications | LPG, LNG |

| Special treatment | Deep cryogenic treatment |

| Special test | Impact test |

| Function 1 | Bolted bonnet |

| Function 2 | Flexible wedge |

| Function 3 | Full bore |

| Structure feature 1 | Extended Bonnet |

| Structure feature 2 | Relief hole on the wedge |

| Structure feature 3 | Provided with drip plate |

| Structure feature 4 | Fire Safety & Anti-static Design |