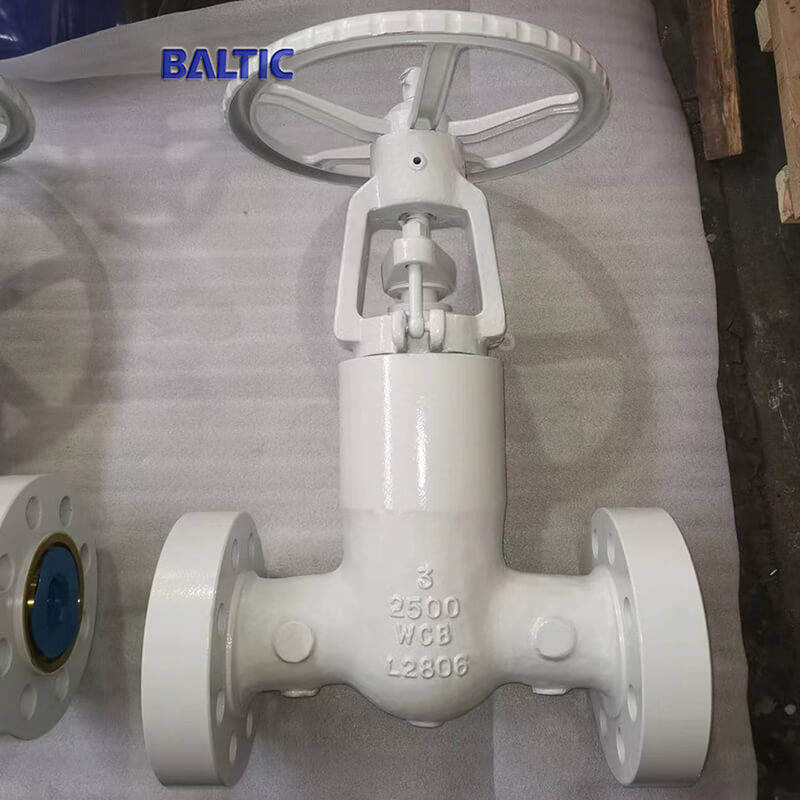

Gate Valve

Main Characteristics:

1. Compact structure, reasonable design, good rigidity of valve, a smooth channel and a small flow coefficient.

2. The sealing surface is made of stainless steel and cemented carbide with long service life.

3. Flexible graphite packing is applied to keep a reliable tight sealing. Operation is portable and flexible.

4. The acuator mode can be by handwheel, pneumatic, electrical and gear box.

5. The structure is elastic single wedge, solid single wedge and double wedges.

The valve cover is self-sealing, which can effectively prevent the leakage of the medium, and is safer and more reliable.

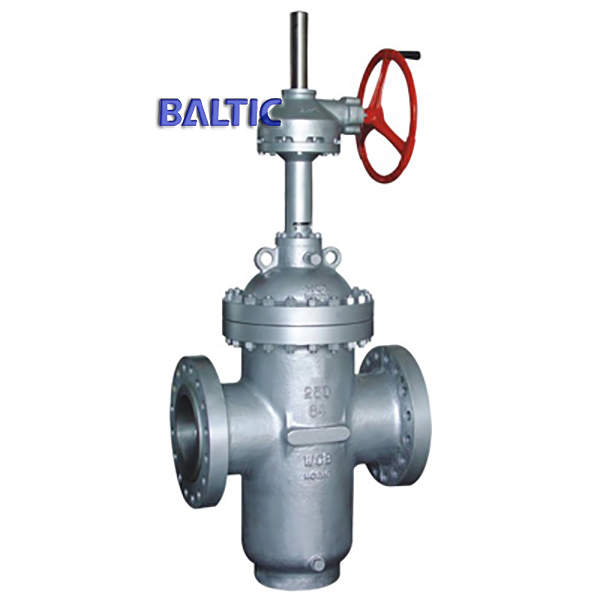

The parallel single gate valve is a kind of single gate valve. It is named because the two sealing surfaces of the gate are parallel and the sealing surface of the valve seat is perpendicular to the center line of the pipeline.

It can not rely on its body to achieve a forced seal but must be fixed or floating soft seat. It is suitable for medium and large caliber, and the medium is oil and natural gas.

Performance advantages:

1. Low fluid resistance.

2. The external force required for opening and closing is small.

3. The flow direction of medium is not limited.

4. When the valve is fully opened, the erosion of the sealing surface by the working medium is smaller than that of the stop valve.

5. The shape is simple and the casting process is good.