Forging Steel Valve

The forging steel valve is mainly used in the pipeline of various systems in thermal power plant for cutting off or connecting the medium. Applicable medium: water, steam and other non-corrosive media. Compared with other valve products, the forged steel valve features high temperature, high pressure and unique self sealing design. The higher the pressure, the more reliable the seal. Due to the special performance, technical characteristics and working conditions, the product can not be replaced by others.

1. The wedge has two sealing faces. The two sealing surface of the most commonly used gate valve forms a wedge, whose angle varies with valve parameters, usually 5°.

2. The sealing principle of the wedge gate valve depends on the close connection of two sealing surfaces of the wedge and two sealing surfaces of the guide slot of the valve body when they are wedged.

3. The valve body and the bonnet may be connected by bolts, pressure self-tight or welding.

4. The wedge is solid.

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer's standard

Flange connecting end: ASME B16.5

Butt welding connecting end: ASME B16.25

Wall thickness: API 602, ASME B16.34

Inspection and test: API 602

Pressure and temperature rating: ASME B16.34

Product scope: NPS 1/2 Inch - NPS 3 Inch, Class 150 - 2500 LB

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

Drive device: handle, bevel gear, electric, pneumatic, etc.

2. The sealing principle of the wedge gate valve depends on the close connection of two sealing surfaces of the wedge and two sealing surfaces of the guide slot of the valve body when they are wedged.

3. The valve body and the bonnet may be connected by bolts, pressure self-tight or welding.

4. The wedge is solid.

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer's standard

Flange connecting end: ASME B16.5

Butt welding connecting end: ASME B16.25

Wall thickness: API 602, ASME B16.34

Inspection and test: API 602

Pressure and temperature rating: ASME B16.34

Product scope: NPS 1/2 Inch - NPS 3 Inch, Class 150 - 2500 LB

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

Drive device: handle, bevel gear, electric, pneumatic, etc.

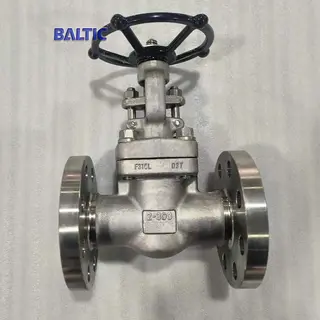

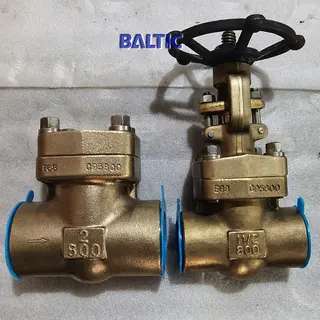

1. A globe valve uses valve stem pressure to make the sealing surface of the disc and sealing surface of valve seat fit tightly to cut off the medium. It's a forced seal valve.

2. Flow direction of the medium in globe valve contains "low in and high out" and "high in and low out". The medium is allowed to flow in only one direction. The valve shall be installed in right direction.

3. Globe valve has structure of straight-through type, direct flow type and right angle type.

4. When a globe valve is open, and the opening height of the disc is up to 25%-30% of nominal diameter of the globe valve, the flow reaches the maximum, which shows that the globe valve is in a fully open position.

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer's standard

Flange connecting end: ASME B16.5

Butt welding connecting end: ASME B16.25

Wall thickness: API 602, ASME B16.34

Inspection and test: API 602

Pressure and temperature rating: ASME B16.34

Product scope: NPS 1/2 Inch - NPS 4 Inch, Class 150 - 4500 LB

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

Drive device: handle, bevel gear, electric, pneumatic, etc.

2. Flow direction of the medium in globe valve contains "low in and high out" and "high in and low out". The medium is allowed to flow in only one direction. The valve shall be installed in right direction.

3. Globe valve has structure of straight-through type, direct flow type and right angle type.

4. When a globe valve is open, and the opening height of the disc is up to 25%-30% of nominal diameter of the globe valve, the flow reaches the maximum, which shows that the globe valve is in a fully open position.

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer's standard

Flange connecting end: ASME B16.5

Butt welding connecting end: ASME B16.25

Wall thickness: API 602, ASME B16.34

Inspection and test: API 602

Pressure and temperature rating: ASME B16.34

Product scope: NPS 1/2 Inch - NPS 4 Inch, Class 150 - 4500 LB

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

Drive device: handle, bevel gear, electric, pneumatic, etc.

The forging steel check valve can automatically open and close with the flow of the medium itself. It's also known as one-way valve, reverse flow valve, and back pressure valve, used to prevent the reverse flow of medium. Check valve is a kind of automatic valve. Its main function is to prevent the reverse flow of the medium, reverse rotation of the pump and the drive motor, and discharge of the medium in the container. The check valve can also be used to supply the auxiliary system where the pressure may rise above the system pressure. A check valve can be divided into swing check valve (rotating according to the center of gravity) and lift check valve (moving along the axis).

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer’s standard

Flange connecting end: ASME B16.5, GB/T 9113, HG/T 20592, EN 1092.1

Butt welding connecting end: ASME B16.25, GB/T 12224

Wall thickness: API 602, ASME B16.34, GB/T 12224

Inspection and test: API 602, GB/T 13927

Pressure and temperature rating: ASME B16.34, EN 12516, GB/T 12224

Product scope: NPS 1/2 Inch - NPS 2 Inch (DN15 - DN50), Class 150 - 2500 LB (PN16 - PN420)

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer’s standard

Flange connecting end: ASME B16.5, GB/T 9113, HG/T 20592, EN 1092.1

Butt welding connecting end: ASME B16.25, GB/T 12224

Wall thickness: API 602, ASME B16.34, GB/T 12224

Inspection and test: API 602, GB/T 13927

Pressure and temperature rating: ASME B16.34, EN 12516, GB/T 12224

Product scope: NPS 1/2 Inch - NPS 2 Inch (DN15 - DN50), Class 150 - 2500 LB (PN16 - PN420)

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

The strainer is an indispensable device for transporting the medium in the pipeline. It is usually installed in the input end of pressure reducing valve, pressure relief valve, level control valve, and other equipment. The filter is made of a cylinder, a stainless steel filter screen, a sewage discharge part, a transmission device and an electrical control part. When the medium passes through the filter screen, its impurities are blocked. For cleaning, just need to take the removable cartridge out and install it again after treatment. Therefore, the usage and maintenance of the strainer are very convenient.

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer's standard

Flange connecting end: ASME B16.5, GB/T 9113, HG/T 20592, EN 1092.1

Butt welding connecting end: ASME B16.25, GB/T 12224

Wall thickness: API 602, ASME B16.34, GB/T 12224

Inspection and test: API 602, GB/T 13927

Pressure and temperature rating: ASME B16.34, EN 12516, GB/T 12224

Product scope: NPS 1/2 Inch - NPS 2 Inch (DN15 - DN50), Class 150 - 2500 LB (PN16 - PN420)

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

Product Detail

Design standard: API 602, BS 5352

The length of the structure: as per manufacturer's standard

Flange connecting end: ASME B16.5, GB/T 9113, HG/T 20592, EN 1092.1

Butt welding connecting end: ASME B16.25, GB/T 12224

Wall thickness: API 602, ASME B16.34, GB/T 12224

Inspection and test: API 602, GB/T 13927

Pressure and temperature rating: ASME B16.34, EN 12516, GB/T 12224

Product scope: NPS 1/2 Inch - NPS 2 Inch (DN15 - DN50), Class 150 - 2500 LB (PN16 - PN420)

Main body material: ASTM A105, ASTM A182 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.