The Structural Characteristics of the Pressure-balanced Plug Valve

The features of the plug valve

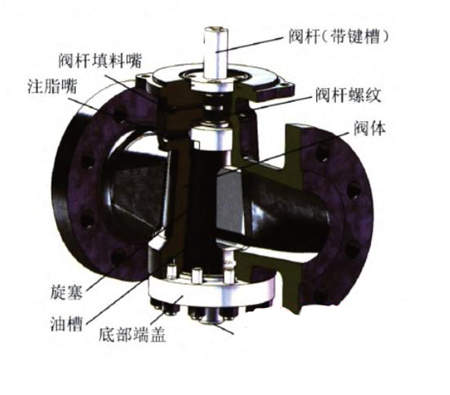

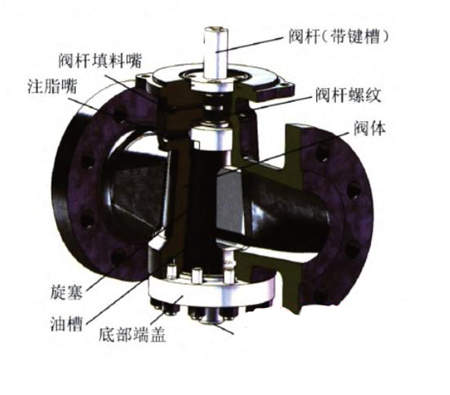

The plug valve uses a plunger body with a through hole as an opening and closing part, and the plunger body rotates 90° with the valve stem to realize the function of connecting or cutting off the fluid in the pipeline. The plug valve is composed of a valve body, a plug, a valve stem and other parts (Figure 1). API 6D-2008 "Oil and Natural Gas Industrial Pipeline Transportation Systems", BS5353-1989 "Steel Plug Valves", API59-2013 "Flanged, Threaded and Welded Metal Plug Valves", ASMEB16.34-2017 "Flanged, Threaded and Welded Valve" and other standard design and manufacturing are mainly implemented for plug valves. The full name of the plug valve is the pressure-balanced upside-down oil-sealed plug valve for oil and gas pipelines. The plug is cone shaped with a big and small end. The bottom is big and the top is small. The plug is installed from the bottom, so it is called the upside-down plug valve; the sealing performance of the valve is enhanced by adding lubricating and sealing grease, so it is called the oil seal.

Figure 1 The schematic diagram of the structure of the plug valve

1.1 Sealing principles

The sealing pair of the plug valve adopts a metal cone seal plus grease seal structure. The surface of the plug including the valve stem is treated by a special technology, which consists of a material with wear resistance, that is, PTFE (polytetrafluoroethylene). After the surface of the plug is treated, it can not only ensure sealing and wear resistance, but also have self-lubricating properties, reducing the opening resistance of the valve, adapting to throttling and scouring of fluids, and extending the service life of the valve. There are four oil grooves on the surface of the plug, from the small end to the big end, two upstream and downstream. When the valve is in the closed position, the sealing grease in the oil groove forms an oil film seal with the inner surface of the valve body (valve seats), which enhances the sealing performance.

1.2 Principles of pressure balance

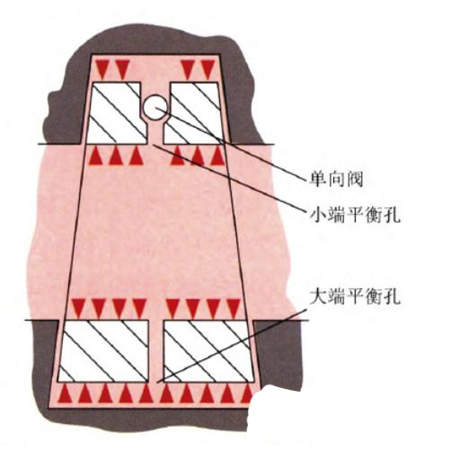

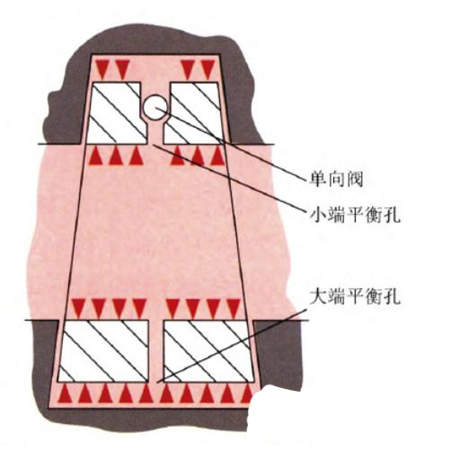

Although the plug and valve seat have the same cone and are precisely ground and matched, the plug actually moves in the direction vertical to the pipe and axial direction in addition to the rotational movement in the valve body, which is similar to the floating ball's structure in the ball valve. According to the pressure balance principle of the plug valve, the plug can move up and down in the valve body. There is an adjustment screw at the bottom of the big end of the plug valve. Tighten the screw and the plug will move up to achieve the purpose of plugging. When the pressure-balanced plug valve is in the closed position, the protruding structure on the top of the plug valve and the groove at the bottom of the valve stem are parallel to the axis of the pipe. This structure can ensure that when the valve is pressurized on one side, the pressure pushes the plug to move slightly to the low-pressure side along the pipeline's axis. A small hole is at the bottom of the big end of the conventional pressure-balanced plug valve, which leads to the small end of the plug. It is the balance hole. There is a one-way valve in the balance hole leading to the small end, and the gas can only flow from the big end to the small end (Figure 2). When the valve is in the closed position, the outer surfaces of the big and small end and the inner surface of the valve respectively form a big end valve cavity and a small end valve cavity. Because there is a balance hole, the air pressure of the two cavities is equal. However, the big end has a big cross-sectional area and a large force, and the small end has a small cross-sectional area and a small force. Therefore, the combined force is upward, and the plug is tightened to make the valve easier to seal. When the valve is opened, the big end will instantly release the pressure. However, there is a one-way valve in the balance hole at the small end, which cannot relieve the pressure. The pressure pushes the plug down to make the valve easier to open.

Figure 2 The schematic diagram of pressure-balanced holes of conventional pressure-balanced plug valves

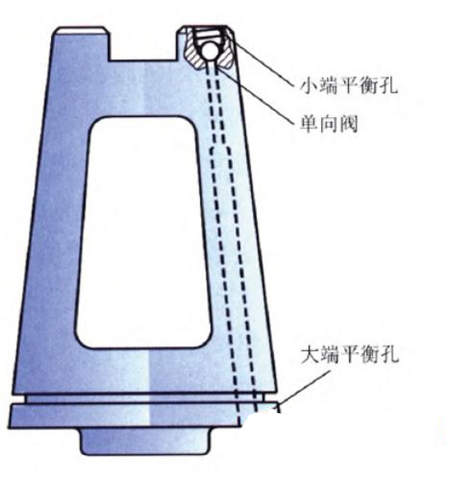

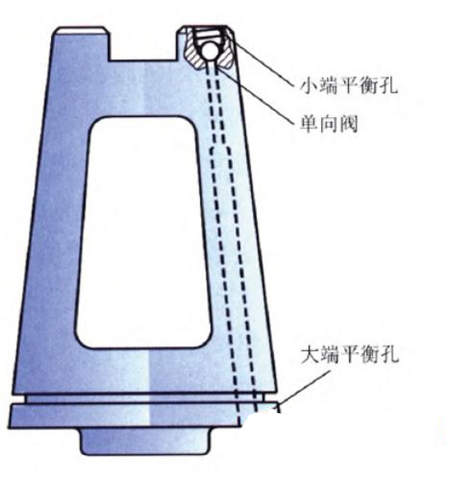

The pressure-balanced hole is bored in the side plug body of the plug. The hole channel does not directly connect the medium channel, which avoids the impurity particles in the medium from getting into the bottom of the big end of the plug. The pressure at the valve cavity of the big end of common plug valves enters from the balanced hole which connects to the medium channel and the pressure is released from the balance hole. However, the pressure of the valve cavity at the big end of Serck Audco plug valves enters and releases through the gap between the big end of the plug and the valve seat of the plug valve. Instant pressure relief is achieved through the gap between the big end and valve seat, which puts forward higher requirements for the machining accuracy and cone design of the plug and valve seat.

Figure 3 The schematic diagram of the pressure-balanced hole of the plug valve

The plug valve uses a plunger body with a through hole as an opening and closing part, and the plunger body rotates 90° with the valve stem to realize the function of connecting or cutting off the fluid in the pipeline. The plug valve is composed of a valve body, a plug, a valve stem and other parts (Figure 1). API 6D-2008 "Oil and Natural Gas Industrial Pipeline Transportation Systems", BS5353-1989 "Steel Plug Valves", API59-2013 "Flanged, Threaded and Welded Metal Plug Valves", ASMEB16.34-2017 "Flanged, Threaded and Welded Valve" and other standard design and manufacturing are mainly implemented for plug valves. The full name of the plug valve is the pressure-balanced upside-down oil-sealed plug valve for oil and gas pipelines. The plug is cone shaped with a big and small end. The bottom is big and the top is small. The plug is installed from the bottom, so it is called the upside-down plug valve; the sealing performance of the valve is enhanced by adding lubricating and sealing grease, so it is called the oil seal.

Figure 1 The schematic diagram of the structure of the plug valve

1.1 Sealing principles

The sealing pair of the plug valve adopts a metal cone seal plus grease seal structure. The surface of the plug including the valve stem is treated by a special technology, which consists of a material with wear resistance, that is, PTFE (polytetrafluoroethylene). After the surface of the plug is treated, it can not only ensure sealing and wear resistance, but also have self-lubricating properties, reducing the opening resistance of the valve, adapting to throttling and scouring of fluids, and extending the service life of the valve. There are four oil grooves on the surface of the plug, from the small end to the big end, two upstream and downstream. When the valve is in the closed position, the sealing grease in the oil groove forms an oil film seal with the inner surface of the valve body (valve seats), which enhances the sealing performance.

1.2 Principles of pressure balance

Although the plug and valve seat have the same cone and are precisely ground and matched, the plug actually moves in the direction vertical to the pipe and axial direction in addition to the rotational movement in the valve body, which is similar to the floating ball's structure in the ball valve. According to the pressure balance principle of the plug valve, the plug can move up and down in the valve body. There is an adjustment screw at the bottom of the big end of the plug valve. Tighten the screw and the plug will move up to achieve the purpose of plugging. When the pressure-balanced plug valve is in the closed position, the protruding structure on the top of the plug valve and the groove at the bottom of the valve stem are parallel to the axis of the pipe. This structure can ensure that when the valve is pressurized on one side, the pressure pushes the plug to move slightly to the low-pressure side along the pipeline's axis. A small hole is at the bottom of the big end of the conventional pressure-balanced plug valve, which leads to the small end of the plug. It is the balance hole. There is a one-way valve in the balance hole leading to the small end, and the gas can only flow from the big end to the small end (Figure 2). When the valve is in the closed position, the outer surfaces of the big and small end and the inner surface of the valve respectively form a big end valve cavity and a small end valve cavity. Because there is a balance hole, the air pressure of the two cavities is equal. However, the big end has a big cross-sectional area and a large force, and the small end has a small cross-sectional area and a small force. Therefore, the combined force is upward, and the plug is tightened to make the valve easier to seal. When the valve is opened, the big end will instantly release the pressure. However, there is a one-way valve in the balance hole at the small end, which cannot relieve the pressure. The pressure pushes the plug down to make the valve easier to open.

Figure 2 The schematic diagram of pressure-balanced holes of conventional pressure-balanced plug valves

The pressure-balanced hole is bored in the side plug body of the plug. The hole channel does not directly connect the medium channel, which avoids the impurity particles in the medium from getting into the bottom of the big end of the plug. The pressure at the valve cavity of the big end of common plug valves enters from the balanced hole which connects to the medium channel and the pressure is released from the balance hole. However, the pressure of the valve cavity at the big end of Serck Audco plug valves enters and releases through the gap between the big end of the plug and the valve seat of the plug valve. Instant pressure relief is achieved through the gap between the big end and valve seat, which puts forward higher requirements for the machining accuracy and cone design of the plug and valve seat.

Figure 3 The schematic diagram of the pressure-balanced hole of the plug valve