Solutions to Internal Leakages of Plug Valves

The ESD high-pressure vent pipe in the station yard is under long-term single sided pressure on the plug valve. The working condition is harsh and frequent internal leakage occurs, and conventional solutions are not good. When internal leakage occurs, it is the same as the continuous venting of the station venting system, which causes energy waste, environmental pollution, and potential safety hazards. According to API 6D 2008, the leakage of the oil-sealed plug valve cannot exceed Class A (no visible leakage) in the Pressure Tests for Industrial Valves ISO 5208-2015. The plug valve is installed in the ESD high-pressure vent pipe and its internal leakage can't be measured by the instrument. Generally, the observational method is used. Touch the valve body and the downstream pipeline by hands, if there isn't a sense of cooling on the surface, or no water droplets are heard, it shows that slight internal leakage happens for the valve. If you feel a sense of cooling when touching the surface of the valve body and its downstream pipeline, water droplets occur on the surface of the valve body or its downstream pipeline, or freezing or frosting even happens in winter, it is believed that the valve has serious internal leakages.

Solutions to internal leakages of plug valves

Solutions to internal leakages of plug valves

1. Grease injection

The plug valve of the ESD high-pressure vent pipe in the station yard should be grease injected at least twice a year. The plug valve that has internal leakages or slight internal leakages caused by lack of grease for the first time can be grease injected. Grease can be injected in the fully closed or opened position, and middle position according to the severity of the internal leakage to ensure sufficient grease injection. In the case of slightly severe internal leakages, you can soak the plug valve in the cleaning agent for 24 hours before injecting grease. This is caused by the aged or saponified grease, losing its sealing performance and causing the internal leakage. The cleaning agent softens and dilutes the old grease, and the injected new grease squeezes the old grease and makes it stay out of the oil groove, realizing the sealing again. If the above methods can not solve the problem, it may be that the valve has been used for too long, and the surface of the plug and inner surface of the valve body is worn; the matching gap becomes larger. You can try to tighten the bottom adjustment screw to make the gap between the plug and valve body, and then inject the grease. However, it should be noted that over tightening the bottom adjustment screw may cause the valve to fail to be opened.

2. Disassembly and repair

If the above methods can not solve the problem, you can try disassembly and repair, that is, disassemble the plug valve. Take the plug out; clean the plug oil groove. Polish the surface of the plug with obvious scratches, and then install the plug valve and inject it with grease. If there is a defect on the plug surface, you can rotate the plug at an angle of 180, that is, the pressure-bearing surface and the non-pressure-bearing surface are exchanged. The disassembly and maintenance remove the hardened, aging, and non viscous sealing grease in the oil groove of the plug, so that the grease injection channel is restored and the sealing grease re-realizes an effective seal.

However, the overall effect of disassembly and repair is not good, and most of the valves quickly experienced internal leakages after repair. The reason for the sealing grease being hardened, aged, and losing its viscosity may be that the sealing performance can be restored by removing the old grease and then injecting the new grease, but it doesn't work for the situations when there are wear, scratches and deformation for the plug and valve body. In addition, the plug and valve body of the plug valve are matched one by one, and the gap between the plug and valve body has been adjusted before leaving the factory. It is difficult to find the matched gap at the time after disassembly, so it is difficult to ensure the sealing effect.

3. Replacing the plug valve

If the disassembly and maintenance still cannot solve the problem, you can consider replacing the plug valve with another kind of plug valve. According to GB 50251-2015 Design Specifications of Gas Pipeline Engineering, when the gas transmission station is equipped with an emergency venting system, the design should meet the requirement of reducing the pressure in the station pipeline and equipment from the initial pressure to 50% of the design pressure within 15 minutes. Imported plug valves are the first choice for ESD vent valves in gas transmission stations due to their fast opening and a large amount of venting. However, the purchase price of imported plug valves is high, and grease maintenance is required. There is a hidden danger, that is, internal leakage, so the throttle globe valve or ball valve is used later. According to CDP-G-GP-OP-001-2009A Guidelines for the Design of Gas Pipeline Engineering, the vent valve should be a throttle globe vent valve or a plug valve. According to CDP-G-NGP-OP-015-2013-1 "Regulations on Station Yard Technology for Gas Transmission Pipeline Engineering", the ESD automatic venting pipeline should be designed with double valves in series, and ball valves should be used for upstream and downstream; a restriction orifice should be installed at the rear. In addition, when selecting the throttle globe vent valve, it is necessary to check whether it can meet the emergency venting conditions of the station. At present, the throttle globe vent valve has been used as an ESD vent valve in some stations of the West Second Line and the east section of the West Third Line. Internal leakage rarely occurs during operation.

4. Returning to factory for repair

Given the high cost of replacing the valve and its long procurement cycle, the plug valve was sent to the factory for maintenance in order to find the root cause of the frequent internal leakage. The maintenance mainly includes disassembly of all valve parts, and measurement of taper between the valve plug and body, grinding, matching and grinding, surface treatment, spraying, leak tests, hydraulic tests, opening and closing tests for valves (full pressure difference).

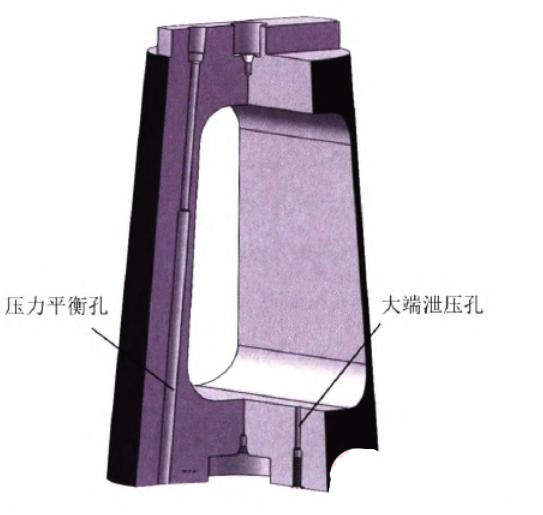

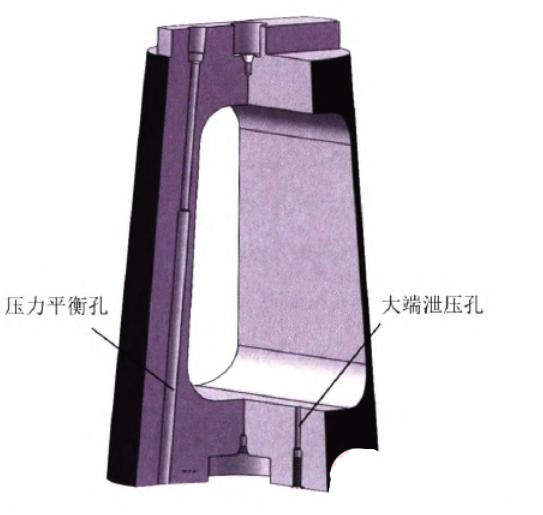

After the above-mentioned maintenance, the plug valve was tested on-site and internal leakages didn't occur. However, there was jamming when the valve was opened with pressure, that is, the valve could be opened when there was no pressure; when the valve with pressure was opened at an angle of 30, the alarm was set off for the electric actuator due to over torque. The manual operation of the valve was not working. The reason was that the pressure holding occurs for the plug valve cavity of the big end after repair after analyzing, that is, when the valve was opened, the pressure at the cavity of the big end could not be released instantly. The pressure at the cavity of the big end pushes the plug upward tightly, and the self-locking of the cock cone appears.

In order to solve the problem of self-locking of the cock cone, the maintenance process has been improved. The large end of the plug was provided with a pressure relief hole that directly connects with the medium flow channel to ensure that the large end valve cavity instantly released pressure when the valve was opened. After improving the maintenance process, the jamming was solved when the valve was opened with pressure.

Figure 4 The picture of the large end of the plug valve with a pressure relief hole

2. Disassembly and repair

If the above methods can not solve the problem, you can try disassembly and repair, that is, disassemble the plug valve. Take the plug out; clean the plug oil groove. Polish the surface of the plug with obvious scratches, and then install the plug valve and inject it with grease. If there is a defect on the plug surface, you can rotate the plug at an angle of 180, that is, the pressure-bearing surface and the non-pressure-bearing surface are exchanged. The disassembly and maintenance remove the hardened, aging, and non viscous sealing grease in the oil groove of the plug, so that the grease injection channel is restored and the sealing grease re-realizes an effective seal.

However, the overall effect of disassembly and repair is not good, and most of the valves quickly experienced internal leakages after repair. The reason for the sealing grease being hardened, aged, and losing its viscosity may be that the sealing performance can be restored by removing the old grease and then injecting the new grease, but it doesn't work for the situations when there are wear, scratches and deformation for the plug and valve body. In addition, the plug and valve body of the plug valve are matched one by one, and the gap between the plug and valve body has been adjusted before leaving the factory. It is difficult to find the matched gap at the time after disassembly, so it is difficult to ensure the sealing effect.

3. Replacing the plug valve

If the disassembly and maintenance still cannot solve the problem, you can consider replacing the plug valve with another kind of plug valve. According to GB 50251-2015 Design Specifications of Gas Pipeline Engineering, when the gas transmission station is equipped with an emergency venting system, the design should meet the requirement of reducing the pressure in the station pipeline and equipment from the initial pressure to 50% of the design pressure within 15 minutes. Imported plug valves are the first choice for ESD vent valves in gas transmission stations due to their fast opening and a large amount of venting. However, the purchase price of imported plug valves is high, and grease maintenance is required. There is a hidden danger, that is, internal leakage, so the throttle globe valve or ball valve is used later. According to CDP-G-GP-OP-001-2009A Guidelines for the Design of Gas Pipeline Engineering, the vent valve should be a throttle globe vent valve or a plug valve. According to CDP-G-NGP-OP-015-2013-1 "Regulations on Station Yard Technology for Gas Transmission Pipeline Engineering", the ESD automatic venting pipeline should be designed with double valves in series, and ball valves should be used for upstream and downstream; a restriction orifice should be installed at the rear. In addition, when selecting the throttle globe vent valve, it is necessary to check whether it can meet the emergency venting conditions of the station. At present, the throttle globe vent valve has been used as an ESD vent valve in some stations of the West Second Line and the east section of the West Third Line. Internal leakage rarely occurs during operation.

4. Returning to factory for repair

Given the high cost of replacing the valve and its long procurement cycle, the plug valve was sent to the factory for maintenance in order to find the root cause of the frequent internal leakage. The maintenance mainly includes disassembly of all valve parts, and measurement of taper between the valve plug and body, grinding, matching and grinding, surface treatment, spraying, leak tests, hydraulic tests, opening and closing tests for valves (full pressure difference).

After the above-mentioned maintenance, the plug valve was tested on-site and internal leakages didn't occur. However, there was jamming when the valve was opened with pressure, that is, the valve could be opened when there was no pressure; when the valve with pressure was opened at an angle of 30, the alarm was set off for the electric actuator due to over torque. The manual operation of the valve was not working. The reason was that the pressure holding occurs for the plug valve cavity of the big end after repair after analyzing, that is, when the valve was opened, the pressure at the cavity of the big end could not be released instantly. The pressure at the cavity of the big end pushes the plug upward tightly, and the self-locking of the cock cone appears.

In order to solve the problem of self-locking of the cock cone, the maintenance process has been improved. The large end of the plug was provided with a pressure relief hole that directly connects with the medium flow channel to ensure that the large end valve cavity instantly released pressure when the valve was opened. After improving the maintenance process, the jamming was solved when the valve was opened with pressure.

Figure 4 The picture of the large end of the plug valve with a pressure relief hole