Solutions to Corrosion of Plug Valve Lining

3. Solutions

The plug valve lining is deformed and falls due to the storage and operation of the plug valve and the inherent characteristics of the ordinary PTFE lining, so the existing problems are solved from two aspects, that is selecting materials and structural improvement.

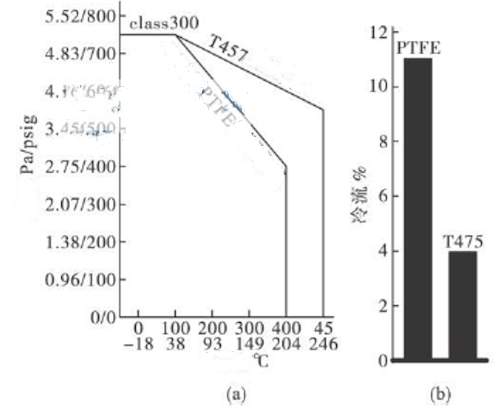

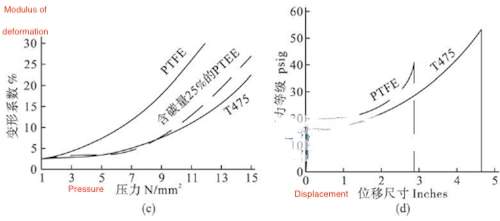

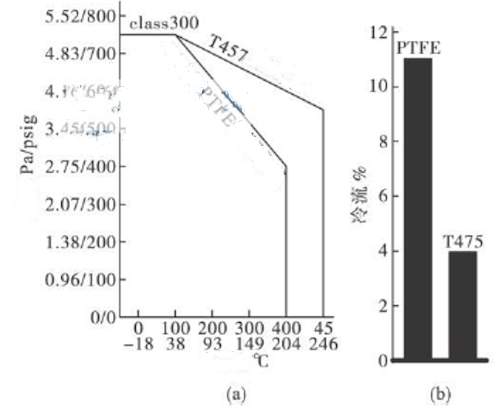

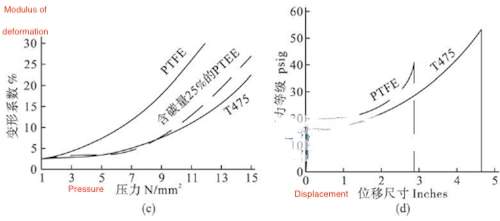

(a) Temperature-pressure change (b) Cold flow characteristics

(c) Pressure-deformation coefficient (d) Pressure-displacement change

Figure 4 Performance analysis of T475 and PTFE

(1) Selecting materials

The ordinary PTFE lining is replaced by T475. The performance of the T475 lining is better (Figure 4). For example, under the pressure of class 300, the performance of ordinary PTFE drops rapidly in the normal temperature control range, while T475 has no obvious performance drop under the same working conditions (Figure 4). Under the pressure level of 15N/mm2 and the temperature of 23, the cold flow of ordinary PTFE is obvious after 100 hours of operation. T475 anti-cold flow effect is 2 to 3 times better than PTFE (Figure 4b). PTFE will be viscous and elastic at any temperature, so flow and creep will occur. The creep and deformation of T475 under load are extremely small, because its microstructure is composed of improved amorphous phase and chain branches. The deformation under load is similar to that of PTFE containing 25% carbon (Figure 4c). Additional testing of the two materials yielded similar results at temperatures up to 150. Although PTFE filled with carbon or glass fibers can resist deformation, the sealing performance is reduced, and the purity is also reduced. The filling is more sensitive to media impact, which also reduces the sealing. T475 is not only resistant to deformation, but its sealing characteristics, medium impact resistance and purity have improved. Tensile load-displacement comparisons show that T475 is more resistant to stress cracking than PTFE (Figure 4d). The surface of T475 is smoother than PTFE, and the smooth surface improves sealing and lubricity, and reduces friction and torque.

(2) Structural improvement

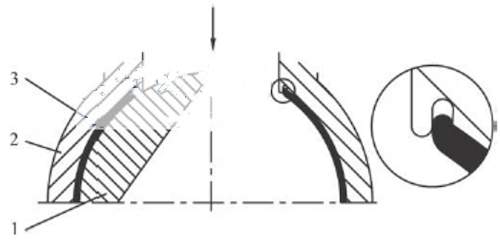

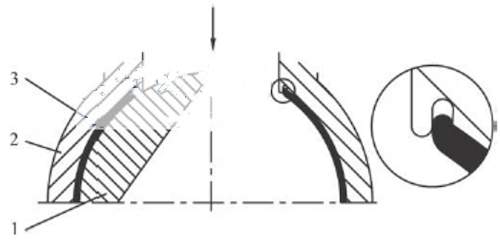

To reduce the influence of factors such as thermal expansion and medium erosion on the lining, the structure of the valve body and the lining has been improved (Figure 5).

1. Plugs 2. Valve bodies 3. Lining

Figure 5 Improvement of valve body structure

When the valve is opened and closed, a certain displacement occurs between the inner lining and the valve body due to the excessive friction between the plug and the inner lining, and the new valve body structure prevents the misalignment of the inner lining material and reduces the damage to the inner lining. To eliminate the influence of the thermal expansion of the lining material, a cavity is provided during the casting of the plug valve, so that the heated expansion part of the lining material will not appear at the flow channel port, and the scouring of the medium is avoided.

4. Conclusion

T475 has a very good preventive effect on the cold flow, excessive friction, frequent temperature fluctuations and thermal expansion of the lining that occur in ordinary PTFE. Through the improvement in the structure of the valve body, the characteristics of the lining material are improved, and the service life of the valve is increased.

The plug valve lining is deformed and falls due to the storage and operation of the plug valve and the inherent characteristics of the ordinary PTFE lining, so the existing problems are solved from two aspects, that is selecting materials and structural improvement.

(a) Temperature-pressure change (b) Cold flow characteristics

(c) Pressure-deformation coefficient (d) Pressure-displacement change

Figure 4 Performance analysis of T475 and PTFE

(1) Selecting materials

The ordinary PTFE lining is replaced by T475. The performance of the T475 lining is better (Figure 4). For example, under the pressure of class 300, the performance of ordinary PTFE drops rapidly in the normal temperature control range, while T475 has no obvious performance drop under the same working conditions (Figure 4). Under the pressure level of 15N/mm2 and the temperature of 23, the cold flow of ordinary PTFE is obvious after 100 hours of operation. T475 anti-cold flow effect is 2 to 3 times better than PTFE (Figure 4b). PTFE will be viscous and elastic at any temperature, so flow and creep will occur. The creep and deformation of T475 under load are extremely small, because its microstructure is composed of improved amorphous phase and chain branches. The deformation under load is similar to that of PTFE containing 25% carbon (Figure 4c). Additional testing of the two materials yielded similar results at temperatures up to 150. Although PTFE filled with carbon or glass fibers can resist deformation, the sealing performance is reduced, and the purity is also reduced. The filling is more sensitive to media impact, which also reduces the sealing. T475 is not only resistant to deformation, but its sealing characteristics, medium impact resistance and purity have improved. Tensile load-displacement comparisons show that T475 is more resistant to stress cracking than PTFE (Figure 4d). The surface of T475 is smoother than PTFE, and the smooth surface improves sealing and lubricity, and reduces friction and torque.

(2) Structural improvement

To reduce the influence of factors such as thermal expansion and medium erosion on the lining, the structure of the valve body and the lining has been improved (Figure 5).

1. Plugs 2. Valve bodies 3. Lining

Figure 5 Improvement of valve body structure

When the valve is opened and closed, a certain displacement occurs between the inner lining and the valve body due to the excessive friction between the plug and the inner lining, and the new valve body structure prevents the misalignment of the inner lining material and reduces the damage to the inner lining. To eliminate the influence of the thermal expansion of the lining material, a cavity is provided during the casting of the plug valve, so that the heated expansion part of the lining material will not appear at the flow channel port, and the scouring of the medium is avoided.

4. Conclusion

T475 has a very good preventive effect on the cold flow, excessive friction, frequent temperature fluctuations and thermal expansion of the lining that occur in ordinary PTFE. Through the improvement in the structure of the valve body, the characteristics of the lining material are improved, and the service life of the valve is increased.