LNG Cryogenic Valves

1. Liquefied natural gas

With the development of industry and the improvement of people's living standards, natural gas, especially liquefied natural gas has become the most indispensable high-quality clean energy for production and lives. The consumption of liquefied natural gas is currently growing at a rate of 10% per year, and is one of the fastest-growing energy markets in the world. Liquefied natural gas (LNG) is an emerging clean and energy-saving energy source. It is generally extracted from gas fields. It needs to be dehydrated under normal pressure, and acid gas and heavy hydrocarbons are separated. Then, it is cooled at a temperature of -162°C. Finally, the usable liquefied natural gas is formed. The liquefied natural gas is mainly composed of methane (CH4), a small amount of ethane (C2H6), propane (C3H8) and impurity. LNG has a boiling point of -162°C, a melting point of -182°C, and an ignition point of 650°C. It has features of light molecular weights, low viscosity, good permeability, being colorless, odorless, non-toxic, non-corrosive, and easy to spread when leaking. It doesn’t generate SO2, NO2 and other air pollutants, which is more environmentally friendly. Moreover, when it is used as vehicle fuel, it has longer mileage and emits less exhaust gas. Therefore, we predict that LNG will replace traditional materials such as gasoline, diesel and coal and become a new type of energy fuel.

2. LNG ultra-low temperature valves

An LNG ultra-low temperature valve is a kind of special valve related to liquefied natural gas, which is widely used in liquefied natural gas production plants, receiving stations, transportation devices, gasification stations and other places. Because of light molecular weights, good permeability, low viscosity, flammability, explosiveness, and vaporization of LNG, an automatic pressure relief structure, an anti-static structure, a fireproof structure, a drip plate structure, a long neck bonnet structure and multiple seals must be adopted for LNG ultra-low temperature valves. Compared with ordinary valves, the design and technical essentials of LNG ultra-low temperature valves are also very different. The first is the selection of materials. Since liquefied natural gas is a special cryogenic fluid that is different from conventional fluids, an operating temperature of -163°C and the characteristics of LNG must be comprehensively considered for the selection of the valve’s material. The second is the sealing of the valve. The error caused by the temperature change must be effectively compensated due to the unstable operating temperature, so a flexible structure is required. In addition, because the working temperature can reach the ultra-low temperature of -163°C, the metal parts of the valve must be cryogenically processed to stabilize the metallographic structure of the material and eliminate possible low-temperature deformation so that the material will not stop working suddenly when it is in use. For some common metals, their strength and toughness may change at very low temperatures. When the working temperature of the valve is lower than -70°C, non-metallic sealing pairs are generally used. At present, PCTFE is adopted as a material for a soft sealing valve seat for Chinese cryogenic ball valves, while metal is selected for the sealing of other cryogenic valves. However, there is a lack of research on the structure and deformation of a metal at low temperatures.

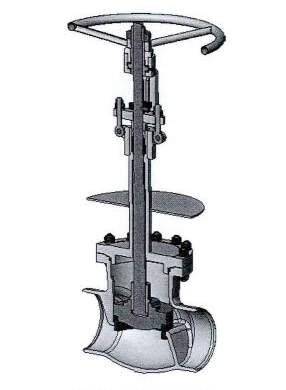

Ultra-low temperature valves used in LNG plants, receiving stations, transportation, gasification stations and other devices are the key devices of LNG projects. A company in China developed ultra-low temperature ball valves, ultra-low temperature gate valves, ultra-low temperature globe valves and ultra-low temperature check valves. Figure 1 is a three-dimensional diagram of the LNG ultra-low temperature globe valve.

Figure 1 The ultra-low temperature globe valve

With the development of industry and the improvement of people's living standards, natural gas, especially liquefied natural gas has become the most indispensable high-quality clean energy for production and lives. The consumption of liquefied natural gas is currently growing at a rate of 10% per year, and is one of the fastest-growing energy markets in the world. Liquefied natural gas (LNG) is an emerging clean and energy-saving energy source. It is generally extracted from gas fields. It needs to be dehydrated under normal pressure, and acid gas and heavy hydrocarbons are separated. Then, it is cooled at a temperature of -162°C. Finally, the usable liquefied natural gas is formed. The liquefied natural gas is mainly composed of methane (CH4), a small amount of ethane (C2H6), propane (C3H8) and impurity. LNG has a boiling point of -162°C, a melting point of -182°C, and an ignition point of 650°C. It has features of light molecular weights, low viscosity, good permeability, being colorless, odorless, non-toxic, non-corrosive, and easy to spread when leaking. It doesn’t generate SO2, NO2 and other air pollutants, which is more environmentally friendly. Moreover, when it is used as vehicle fuel, it has longer mileage and emits less exhaust gas. Therefore, we predict that LNG will replace traditional materials such as gasoline, diesel and coal and become a new type of energy fuel.

2. LNG ultra-low temperature valves

An LNG ultra-low temperature valve is a kind of special valve related to liquefied natural gas, which is widely used in liquefied natural gas production plants, receiving stations, transportation devices, gasification stations and other places. Because of light molecular weights, good permeability, low viscosity, flammability, explosiveness, and vaporization of LNG, an automatic pressure relief structure, an anti-static structure, a fireproof structure, a drip plate structure, a long neck bonnet structure and multiple seals must be adopted for LNG ultra-low temperature valves. Compared with ordinary valves, the design and technical essentials of LNG ultra-low temperature valves are also very different. The first is the selection of materials. Since liquefied natural gas is a special cryogenic fluid that is different from conventional fluids, an operating temperature of -163°C and the characteristics of LNG must be comprehensively considered for the selection of the valve’s material. The second is the sealing of the valve. The error caused by the temperature change must be effectively compensated due to the unstable operating temperature, so a flexible structure is required. In addition, because the working temperature can reach the ultra-low temperature of -163°C, the metal parts of the valve must be cryogenically processed to stabilize the metallographic structure of the material and eliminate possible low-temperature deformation so that the material will not stop working suddenly when it is in use. For some common metals, their strength and toughness may change at very low temperatures. When the working temperature of the valve is lower than -70°C, non-metallic sealing pairs are generally used. At present, PCTFE is adopted as a material for a soft sealing valve seat for Chinese cryogenic ball valves, while metal is selected for the sealing of other cryogenic valves. However, there is a lack of research on the structure and deformation of a metal at low temperatures.

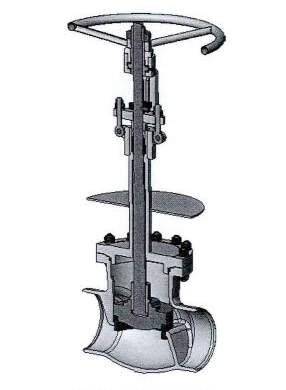

Ultra-low temperature valves used in LNG plants, receiving stations, transportation, gasification stations and other devices are the key devices of LNG projects. A company in China developed ultra-low temperature ball valves, ultra-low temperature gate valves, ultra-low temperature globe valves and ultra-low temperature check valves. Figure 1 is a three-dimensional diagram of the LNG ultra-low temperature globe valve.

Figure 1 The ultra-low temperature globe valve