The Application of DBB Ball Valves to Offshore Oil Platforms

Abstract: Since offshore platforms have strict requirements in terms of space, quality and safety, a new type of integrated DBB valve came into being. The sealing principle and structural form of DBB valves are expounded, and their application advantages on offshore platforms are analyzed in detail. Taking a platform in the South China Sea as an example, the use of DBB valves on the offshore platform reduces the weight by 63 tons and the space by 10%. In terms of safety, the sealing is better due to the reduction of leakage points.

1. Overview

In offshore engineering, there are strict restrictions on space and quality due to the difference in equipment layout between offshore platforms and land oil and gas projects. Therefore, under the premise of ensuring the complete performance and reliability of the equipment, reducing the weight and the volume can greatly reduce the cost and difficulty of the construction of the offshore platform. The emergence of the integrated DBB ball valve is just in line with this concept.

2. The sealing principle of the DBB ball valve

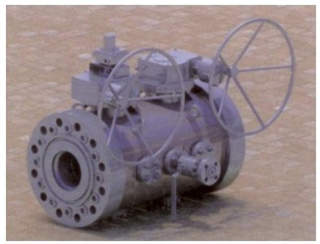

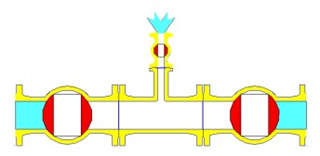

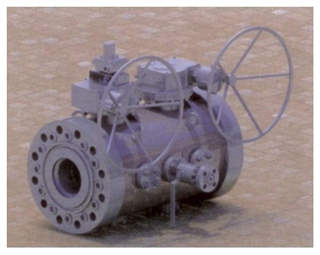

DBB ball valves adopt a single-body double-ball structure, which integrates a valve combination device of traditional structure into a valve. This structure not only greatly reduces the overall space and quality of the valve, but also does not reduce the function. Figure 1 is a traditional valve combination device, and Figure 2 is a typical DBB valve.

Figure 1 Traditional valve combination devices

Figure 2 Typical DBB valves

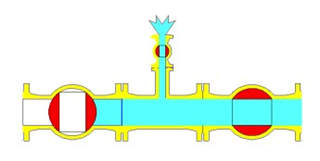

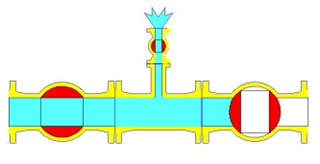

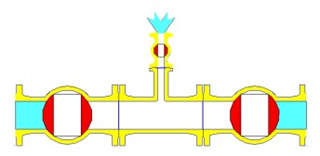

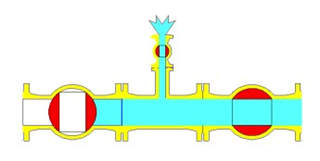

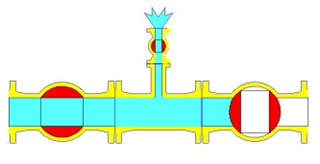

DBB ball valves consist of 2 balls and 4 valve seats. When the 2 balls are closed at the same time, after the upstream and downstream are subjected to the medium pressure, the piston force generated by the piston effect caused by the area difference causes the sealing ring to elastically deform and the sealing surface to be closely attached to the surface of the sphere, generating the sealing force, making the valve ball and the valve seat pressed tightly, and realizing the sealing effect. Since there are two valve seats upstream and downstream, the double sealing effect can be achieved, as shown in Figure 3. The residual medium in the valve cavity can be discharged through the valve body's external device relief valve. The 2 balls can also be closed separately, which is equivalent to a common ball valve and has a sealing effect, as shown in Figure 4 and Figure 5. In the actual use process, if the sealing of one ball fails, the other ball can still play a sealing effect to ensure the normal operation of the pipeline.

Figure 3 Relieving pressure after the closing of the double valve

Figure 4 Relieving pressure after the closing of the right valve

Figure 5 Relieving pressure after the closing of the left valve

3. The structural analysis of DBB double ball valves in offshore platforms

There are two commonly used structural forms of DBB double ball valves. One is compact, and the structure is shown in Figure 6, which is connected to the pipeline with threads. The advantage of this structure is that the end-to-end length of the DBB double ball valve has the same size and specification as that of the single ball valve. The disadvantage is that the single-head bolt used for the connection is too long, and the thread of the connection end is easily damaged during on-site installation or later maintenance, resulting in failing to connect. Therefore, this structure is not widely promoted on offshore platforms. The other is the DBB valve with flange ends. The structure is shown in Figure 7. The end connection of this structure is a traditional flange connection, which is more reliable, and the on-site construction is relatively mature. It is more widely used on offshore platforms.

Figure 6 Compact DBB valves

Figure 7 DBB valves with flange ends

4. The advantages of DBB double ball valves on offshore platforms

4.1 Weights and space

The offshore platform is limited by its manufacturing costs and space, and has strict requirements on quality. How to reduce weight has become a key factor in the design of the platform. Taking a platform in the South China Sea as an example, the entire platform uses 182 DBB valves. The total weight is reduced by 63 tons, and the space is reduced by 10%, which plays a vital role in reducing the platform's weight.

4.2 The analysis of the economy

Taking a platform in the South China Sea as an example, after replacing two single ball valves with DBB integrated double ball valves, the valve procurement cost was saved by about 3.2 million RMB, and the on-site construction was reduced by 546 welding joints, saving 1,200 installation man-hours and reducing RT for 364 times, with a total saving of 4.9 million RMB, which is in line with the current concept of energy conservation and emission reduction.

4.3 Quality and safety

After the one-piece double ball valve is used to replace the two single ball valves, on the one hand, the joints and leakage points are reduced, which can effectively reduce the risk of leakages of high-pressure oil and gas, and the safety has been greatly improved. On the other hand, by looking up the data, SHELL's standard system has corresponding specifications for DBB valves. After the DBB valve adopts an integrated double ball design, with the overall design, the strength of the valve shell is not only higher than that of two valves in series, but the overall bending moment resistance of the valve has been greatly improved and the safety is better.

1. Overview

In offshore engineering, there are strict restrictions on space and quality due to the difference in equipment layout between offshore platforms and land oil and gas projects. Therefore, under the premise of ensuring the complete performance and reliability of the equipment, reducing the weight and the volume can greatly reduce the cost and difficulty of the construction of the offshore platform. The emergence of the integrated DBB ball valve is just in line with this concept.

2. The sealing principle of the DBB ball valve

DBB ball valves adopt a single-body double-ball structure, which integrates a valve combination device of traditional structure into a valve. This structure not only greatly reduces the overall space and quality of the valve, but also does not reduce the function. Figure 1 is a traditional valve combination device, and Figure 2 is a typical DBB valve.

Figure 1 Traditional valve combination devices

Figure 2 Typical DBB valves

DBB ball valves consist of 2 balls and 4 valve seats. When the 2 balls are closed at the same time, after the upstream and downstream are subjected to the medium pressure, the piston force generated by the piston effect caused by the area difference causes the sealing ring to elastically deform and the sealing surface to be closely attached to the surface of the sphere, generating the sealing force, making the valve ball and the valve seat pressed tightly, and realizing the sealing effect. Since there are two valve seats upstream and downstream, the double sealing effect can be achieved, as shown in Figure 3. The residual medium in the valve cavity can be discharged through the valve body's external device relief valve. The 2 balls can also be closed separately, which is equivalent to a common ball valve and has a sealing effect, as shown in Figure 4 and Figure 5. In the actual use process, if the sealing of one ball fails, the other ball can still play a sealing effect to ensure the normal operation of the pipeline.

Figure 3 Relieving pressure after the closing of the double valve

Figure 4 Relieving pressure after the closing of the right valve

Figure 5 Relieving pressure after the closing of the left valve

3. The structural analysis of DBB double ball valves in offshore platforms

There are two commonly used structural forms of DBB double ball valves. One is compact, and the structure is shown in Figure 6, which is connected to the pipeline with threads. The advantage of this structure is that the end-to-end length of the DBB double ball valve has the same size and specification as that of the single ball valve. The disadvantage is that the single-head bolt used for the connection is too long, and the thread of the connection end is easily damaged during on-site installation or later maintenance, resulting in failing to connect. Therefore, this structure is not widely promoted on offshore platforms. The other is the DBB valve with flange ends. The structure is shown in Figure 7. The end connection of this structure is a traditional flange connection, which is more reliable, and the on-site construction is relatively mature. It is more widely used on offshore platforms.

Figure 6 Compact DBB valves

Figure 7 DBB valves with flange ends

4. The advantages of DBB double ball valves on offshore platforms

4.1 Weights and space

The offshore platform is limited by its manufacturing costs and space, and has strict requirements on quality. How to reduce weight has become a key factor in the design of the platform. Taking a platform in the South China Sea as an example, the entire platform uses 182 DBB valves. The total weight is reduced by 63 tons, and the space is reduced by 10%, which plays a vital role in reducing the platform's weight.

4.2 The analysis of the economy

Taking a platform in the South China Sea as an example, after replacing two single ball valves with DBB integrated double ball valves, the valve procurement cost was saved by about 3.2 million RMB, and the on-site construction was reduced by 546 welding joints, saving 1,200 installation man-hours and reducing RT for 364 times, with a total saving of 4.9 million RMB, which is in line with the current concept of energy conservation and emission reduction.

4.3 Quality and safety

After the one-piece double ball valve is used to replace the two single ball valves, on the one hand, the joints and leakage points are reduced, which can effectively reduce the risk of leakages of high-pressure oil and gas, and the safety has been greatly improved. On the other hand, by looking up the data, SHELL's standard system has corresponding specifications for DBB valves. After the DBB valve adopts an integrated double ball design, with the overall design, the strength of the valve shell is not only higher than that of two valves in series, but the overall bending moment resistance of the valve has been greatly improved and the safety is better.