Operating features of globe valves

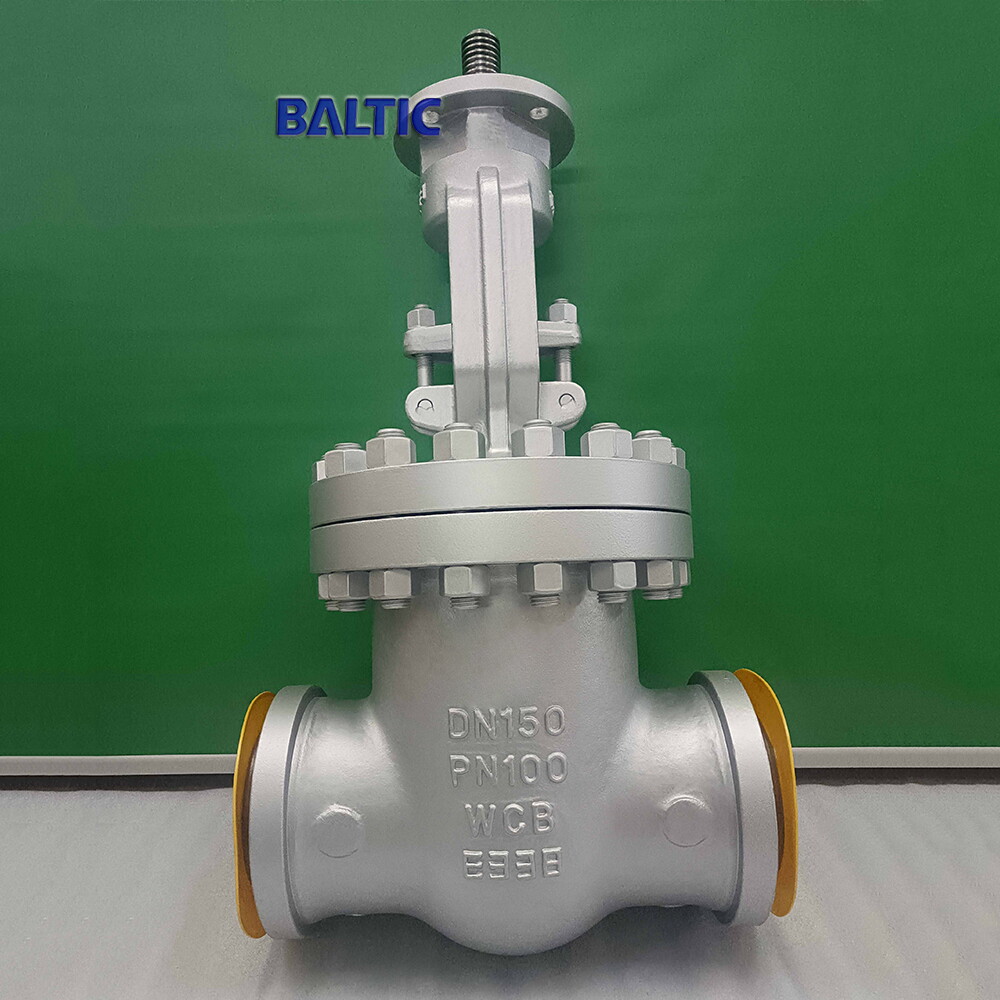

The sealing form of the globe valve is the force seal. When the valve is closed, in order to seal the globe valve, sufficient force must be applied to the valve clack so as to reach necessary sealing pressure. The sealing force and the medium pressure are on the same axis. When the medium enters the lower part of the valve clack, the closing torque of the globe valve is much larger than that of the opening torque, because the directions of medium pressure and the sealing force are opposite. The maximum stress the valve stem bears is pressure stress. Therefore, the valve stem must have enough strength and rigidity. Otherwise, the valve stem will deform flexibly. Because of this, when the size of the globe valve is larger than DN150 (NPS6), the medium flow is usually changed from the lower part to the upper part of the valve in order to reduce the valve operating torque and to reduce the diameter of the stem. The medium pressure and the sealing force have the same direction. The valve can be sealed more easily under the effect of the medium pressure.

When the globe valve is closed, the torque is smaller. When the globe valve is opened, the torque is increased. The maximum stress on the valve stem is tensile stress. And the diameter of the valve stem can be reduced accordingly.

When the globe valve is opened, the opening height of the valve clack reaches 25%~30% of the nominal size of the globe valve. The flow rate has reached the maximum, indicating that the valve has reached the fully open position.

Sealing of a globe valve is similar to force seal of a gate valve, when a globe valve is closed and then opened again. When a globe valve is closed, apply enough operating force on the sealing surface to seal the valve. Therefore, the closing torque of the globe valve should be increased to a certain value based on the operating torque. When the globe valve is opened again, the opening torque of the globe valve is usually larger than the closed torque of the globe valve in order to reliably open the globe valve because of the influence of static friction and thermal expansion.

In order to reduce the high impact pressure, the globe valve needs to be operated slowly when it is opened or closed. In a sense, a rate of change should be consistent with the flow rate.

When the globe valve is closed, the torque is smaller. When the globe valve is opened, the torque is increased. The maximum stress on the valve stem is tensile stress. And the diameter of the valve stem can be reduced accordingly.

When the globe valve is opened, the opening height of the valve clack reaches 25%~30% of the nominal size of the globe valve. The flow rate has reached the maximum, indicating that the valve has reached the fully open position.

Sealing of a globe valve is similar to force seal of a gate valve, when a globe valve is closed and then opened again. When a globe valve is closed, apply enough operating force on the sealing surface to seal the valve. Therefore, the closing torque of the globe valve should be increased to a certain value based on the operating torque. When the globe valve is opened again, the opening torque of the globe valve is usually larger than the closed torque of the globe valve in order to reliably open the globe valve because of the influence of static friction and thermal expansion.

In order to reduce the high impact pressure, the globe valve needs to be operated slowly when it is opened or closed. In a sense, a rate of change should be consistent with the flow rate.