Choosing Valves Based on Different Functions

First, we need to master performance flow characteristics, temperature, pressure and flow rates of media, and then combine them with technology, operation, safety and other factors in order to choose valves with the corresponding types, structures and specifications.

Choosing valves based on flow characteristics

Valve discs and shapes of flow paths of valves make valve have a certain flow characteristic. When choosing a valve, we must take this into account.

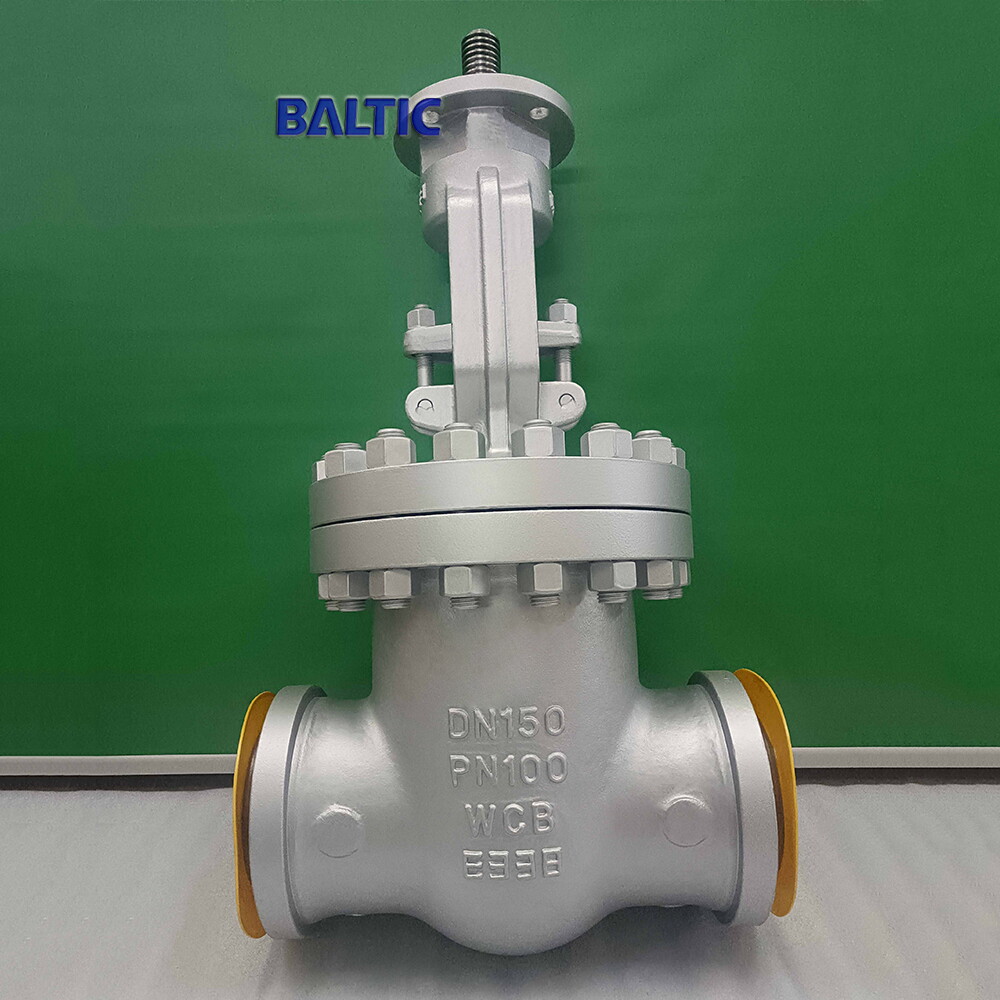

(1) Valves for cutting off and connecting media

Valves for cutting off and connecting media are usually valves with smaller flow resistance and straight through flow paths. These kinds of valves are gate valves, globe valves and plunger valves. Downward closed valves are hardly selected due to their tortuous flow paths and higher flow resistance. However, downward closed valves can be chosen where there is higher flow resistance.

(2) Valves for controlling flows

Regulating valves, throttle valves and plunger valves are often selected to control flows, because their valve seats' sizes are directly proportional to valve discs' routes. Rotary valves such as plug valves, ball valves and butterfly valves and flexible valves like pinch valves and diaphragm valves can also be used for controlling flows, but only a few rotary and flexible valves with a certain range of diameters can be used. In most cases, people often change the shape of the globe valve's clack so as to throttle flows. It should be pointed out that it is unreasonable to achieve the throttling effect by changing the opening height of the gate valve or the globe valve, because the medium in the pipeline has very high flow rate in the state of throttling flows, which will make sealing surface be easily worn and lose cutting and sealing effects. In the same way, using throttle valves as cutting devices is also unreasonable.

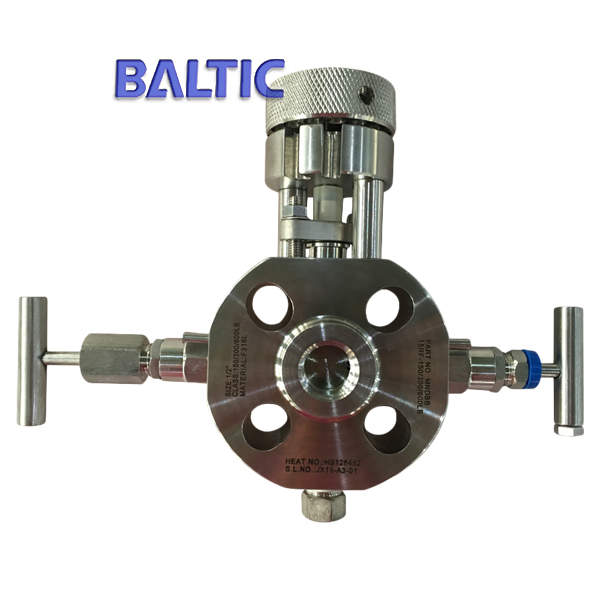

(3) Valves for changing directions and throttling flows

Valves for changing directions and throttling flows require to have two or more than two flow paths. Plug valves and ball valves can be selected based on the requirements of changing directions and throttling flows. In some cases, two or more than two types of valves connected to each other can also be used to change directions and throttle flows.

(4) Valves for media with suspended particles

If the media are the media with suspended particles, flat gate valves are most suitable for them.

Choosing valves based on flow characteristics

Valve discs and shapes of flow paths of valves make valve have a certain flow characteristic. When choosing a valve, we must take this into account.

(1) Valves for cutting off and connecting media

Valves for cutting off and connecting media are usually valves with smaller flow resistance and straight through flow paths. These kinds of valves are gate valves, globe valves and plunger valves. Downward closed valves are hardly selected due to their tortuous flow paths and higher flow resistance. However, downward closed valves can be chosen where there is higher flow resistance.

(2) Valves for controlling flows

Regulating valves, throttle valves and plunger valves are often selected to control flows, because their valve seats' sizes are directly proportional to valve discs' routes. Rotary valves such as plug valves, ball valves and butterfly valves and flexible valves like pinch valves and diaphragm valves can also be used for controlling flows, but only a few rotary and flexible valves with a certain range of diameters can be used. In most cases, people often change the shape of the globe valve's clack so as to throttle flows. It should be pointed out that it is unreasonable to achieve the throttling effect by changing the opening height of the gate valve or the globe valve, because the medium in the pipeline has very high flow rate in the state of throttling flows, which will make sealing surface be easily worn and lose cutting and sealing effects. In the same way, using throttle valves as cutting devices is also unreasonable.

(3) Valves for changing directions and throttling flows

Valves for changing directions and throttling flows require to have two or more than two flow paths. Plug valves and ball valves can be selected based on the requirements of changing directions and throttling flows. In some cases, two or more than two types of valves connected to each other can also be used to change directions and throttle flows.

(4) Valves for media with suspended particles

If the media are the media with suspended particles, flat gate valves are most suitable for them.